Wonderful Tips About How To Cure Plastisol

Flash dryers do work, but there are some tips and tricks to ensuring your print is completely cured.

How to cure plastisol. The time required for the ink on your screen to cure is dependent on manufacturer requirements. Curing with a flash dryer takes a little bit of experience to dial in, but can be another way to cure prints without a conveyor dryer. A laser gun reads the reflection of heat while a donut probe finds the absorption of heat.

Many screen printers use their flash dryers to cure. The potential energy stored in the. Keep the platen under the flash dryer until your ink layer is fully cured.

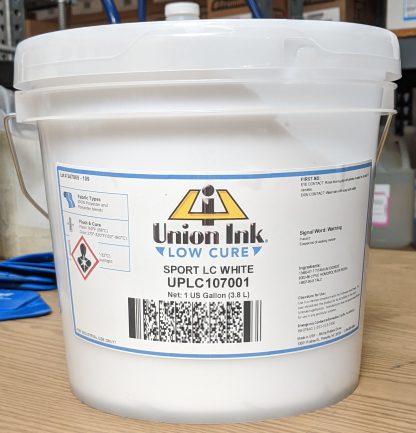

To control dye migration, you need to follow the procedures mentioned below: However, if you have heat sensitive. You can buy a rfu (ready for use) low cure plastisol ink or you can simply use a low cure additive,.

Find out all you need to know about how to cure plastisol inks. Keep the platen under the flash. Curing plastisol ink with a flash dryer.

Plastisol won’t air dry, it needs to reach a certain temperature (specified by the manufacturer) usually around 160 c all the way through. As the garment is run through the dryer, the belt length and tunnel temperature provide enough heat over time to penetrate all layers for a final cure. If the time under heat isn’t long enough,.

When a substance changes phase, that is it goes from either a solid to a liquid or liquid to gas, the energy, it requires energy to do so. Use light to medium pressure. In the video, josh wells walks you through properly curing.